Applications

Sieving and production quality control

Sieve correlation

The weighting of fractions retained in a series of sieves is a reference method that has been used for decades and is duly normalized. Image analysis techniques, only when properly implemented, correlate with the results of sieving and enable you to conduct fast and reliable analyses.

Zephyr ESR and Zephyr LDA make it easy and are designed to replace sieve analysis with controlled particle dispersion and fast, high quality image acquisition. Then, using our patented Callisto software, the machine automatically sorts the optical data, reading each particle and storing the data. You are then able to review this data, along with all the automatically generated reports and accompanying graphs (e.g. size, shape, morphology, abrasiveness, satellite detection and dozens more) This gives you a very accurate and easy to interpret, sieve size distribution curve…without the need to move, change, or clean a single sieve! Moreover, because particles are perfectly focused, and the magnification ratio is known, no obscure calibration procedure is required. Image analysis, by viewing each individual particle, achieves incredible accuracy in size distribution, with only a fraction of the material employed to reach similar precision with sieving methods.

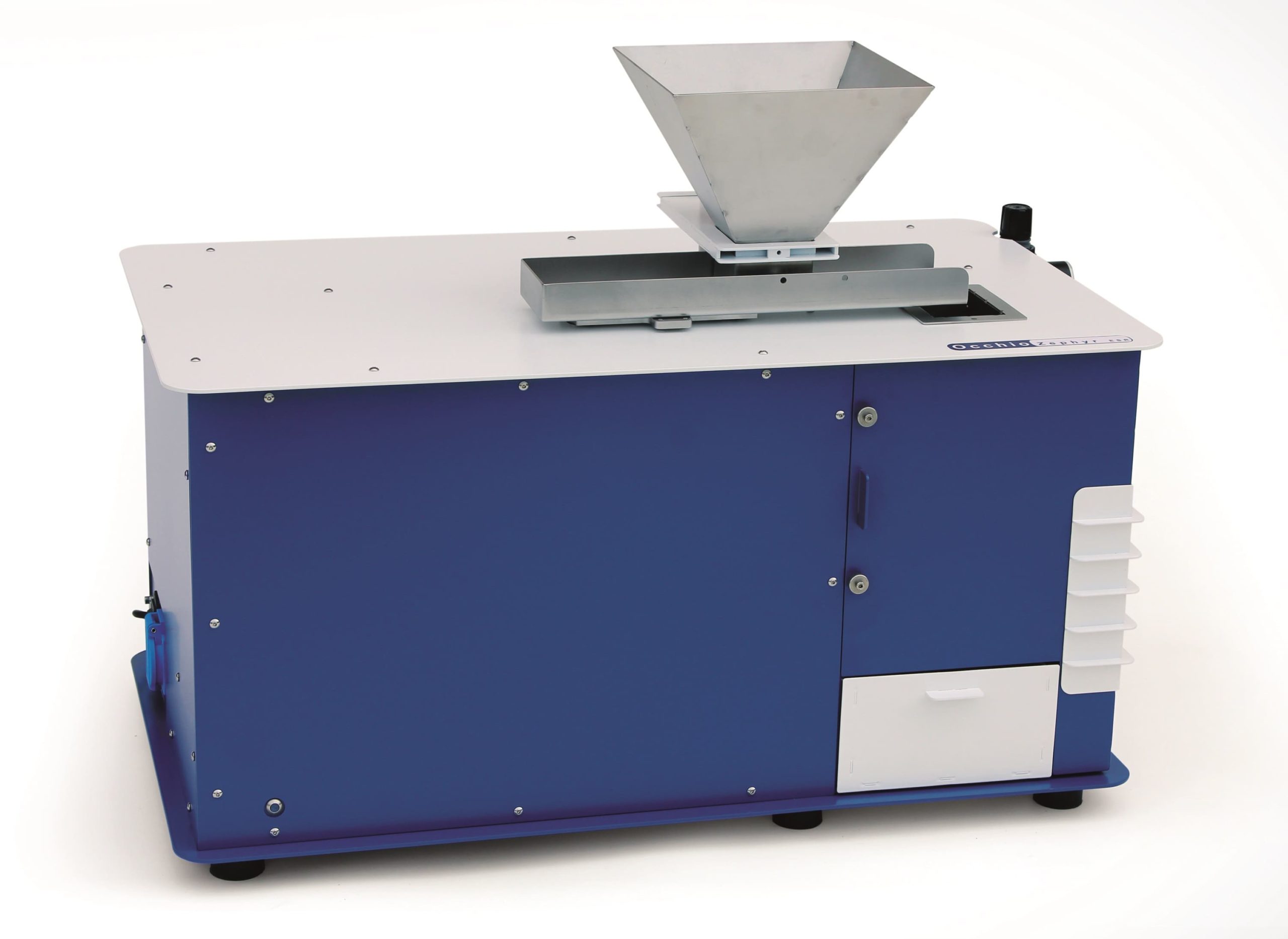

Zephyr ESR

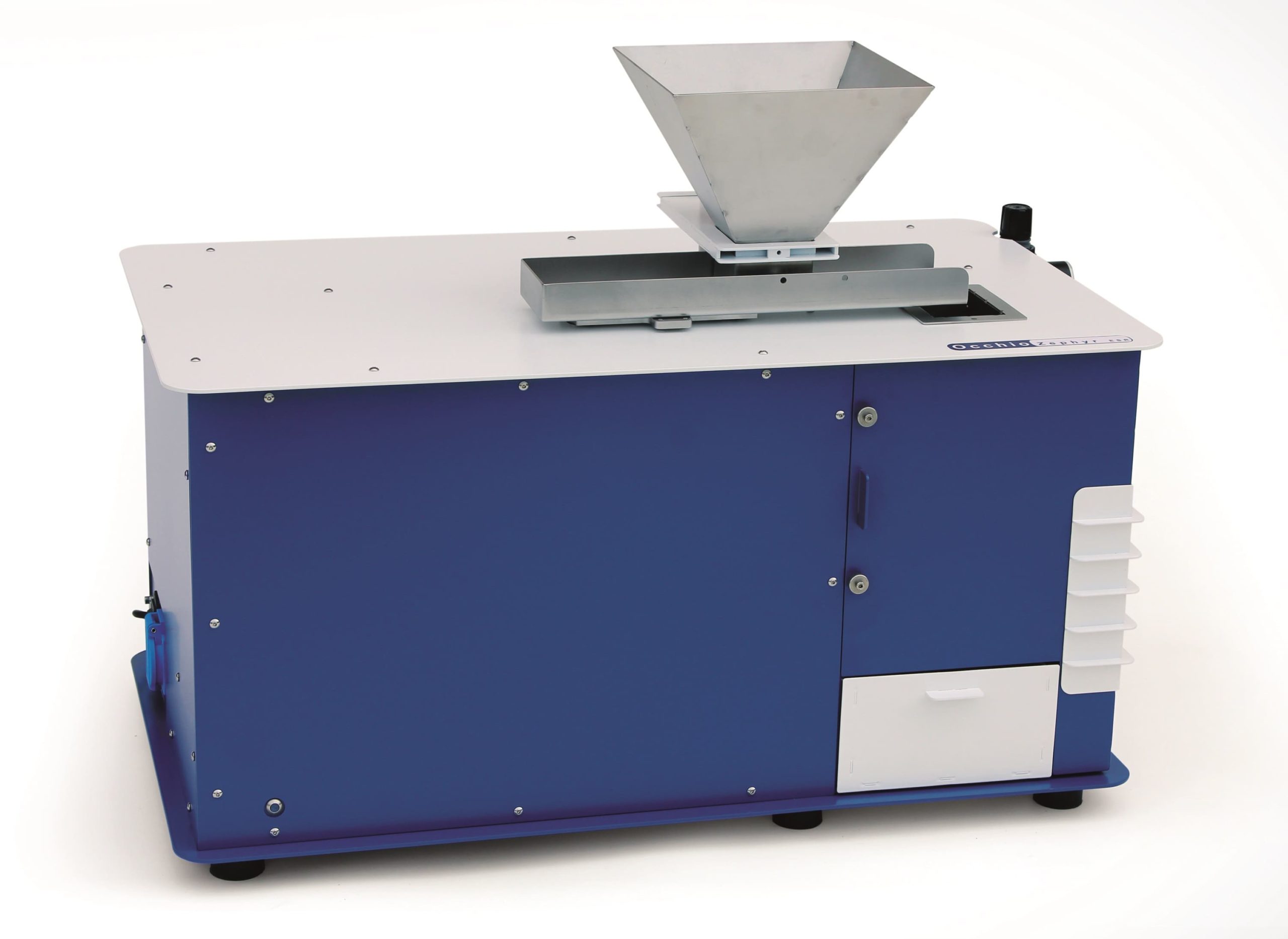

Zephyr LDA

Production quality control

Quality control is becoming increasingly important in industrial production. If you are not sure about choosing one of our instruments, please consider the following:

- You will reduce your money spent on quality control: time of analysis and sample size are reduced, requiring only one operator

- Automatic interpretation of measurements: no need for entering data manually, no risk of error, simultaneous analysis and recording of several parameters all at once

- Perfect correlation with the results of laboratory sieving: perfect continuity of measurements, no alterations to standards for your customers

- Variety of analyzed parameters, development of parameters specific to your sector: roundness, roughness, crystallinity, reactivity, hole detection, satellites detection, convexity, angularity, elongation… etc.

- Unprecedented accuracy by direct measurment

- Robust industrial housing, reducing wear and cleaning intervals

- Users’ training and maintenance programs

- System customizable as a whole according to your specific needs

- Easy and safe to use

- On-line implementation for an automated periodical quality control

- Lower rejection rate thanks to quick default detection (real time analysis and results)

- Higher customer satisfaction

Zephyr ESR

Zephyr LDA